There are three basic forms of X-Ray inspection equipment: manual, semi-automatic and fully automatic. In general, X-Ray inspection equipment can be used at every

different stage of the manufacturing process. Including: component input, process monitoring, quality control and fault analysis. The operator analyzes the X-Ray image

by estimation to determine which defects to show. The test provided by the device is very flexible and can speed up operation time. No expensive training or equipment

programming is required.

The semi-automatic X-Ray inspection equipment is equipped with a mechanical observation and device position programmable console, and the comprehensive analysis

of the device patch and weld points is based on preset grayscale parameters. The setup of the program can generally be based on a quality that has been determined to

determine the initial setup of the PCB assembly board or the use of CAD(computer Aided design) patch information and Navigation procedures. Compared to semi-autom

atic operating equipment, semi-automatic X-ray inspection equipment has a fairly reliable productivity.

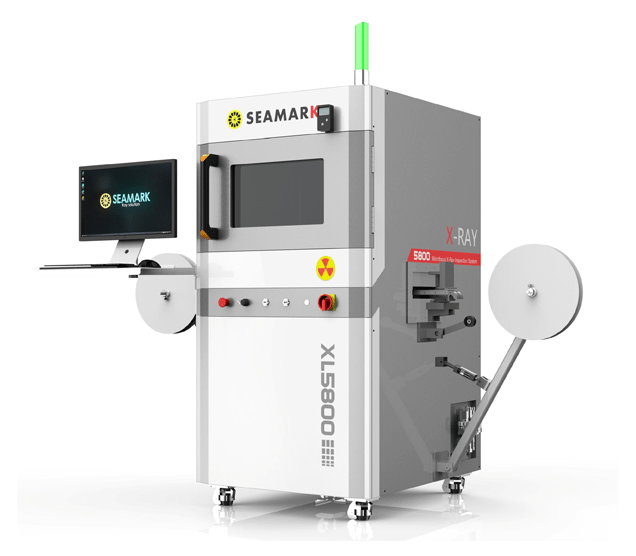

The automatic X-Ray inspection equipment is generally used in places with high yield and low complexity, and is characterized by the use of transmission tape technology

and is designed at a linear rate. All detection work is automated and its operation is mainly based on image analysis.

The above is the three forms of X-Ray inspection equipment, I hope to help you